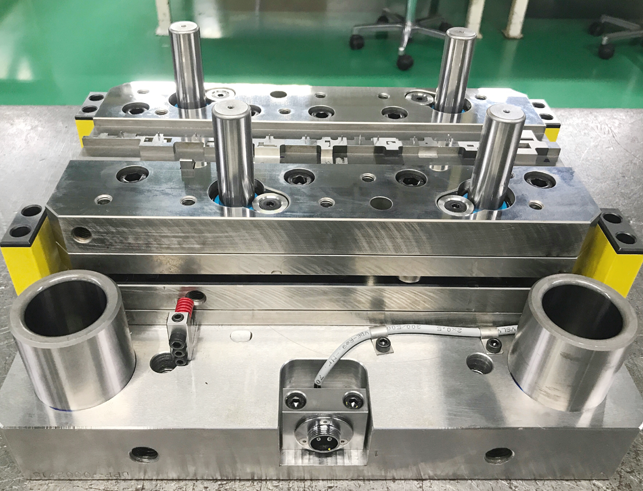

ELLWOOD Aluminum is a premier aluminum supplier, manufacturing cast plates with ultra-high-performance alloys optimized for plastic mold tooling plates. We specifically engineer to maximize the operational advantages of using aluminum alloys for today’s molding technologies, including injection molding, RIM, structural foam molding, vacuum forming, blow molding, rubber molding, tire molding, composite tooling and molds, as well as thermoforming molds.

Aluminum Cast Plate Advantages

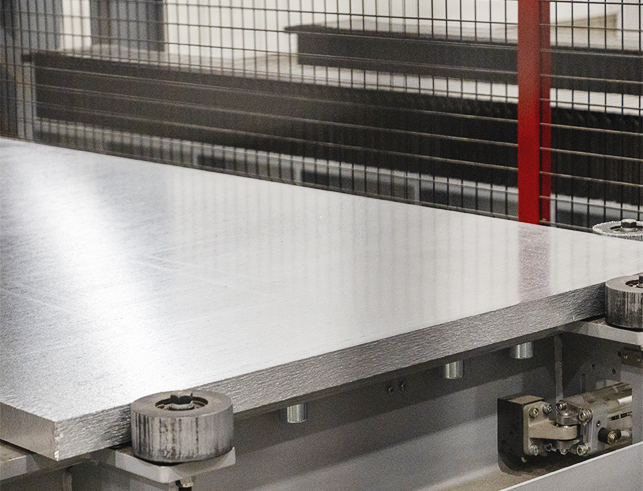

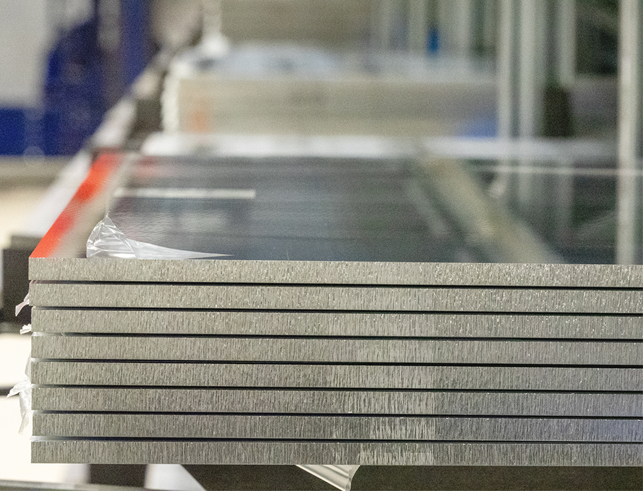

Many choose aluminum cast plates because they are faster and less costly to fabricate than steel. In addition, aluminum is easier to handle and stock since it weighs significantly less. The thermal conductivity of aluminum plates is higher than steel, so aluminum can cut molding cycle times to help you increase your output. Large aluminum castings also allow the molds to cool more evenly, minimizing the risk of distortion in the molded part.

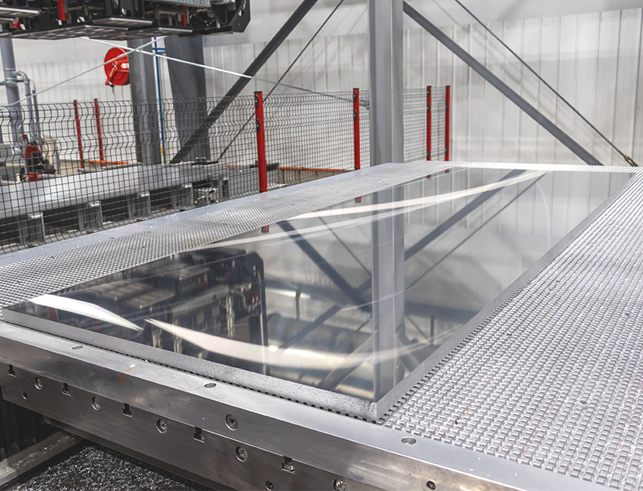

Our advanced aluminum foundry specializes in creating superior-quality cast aluminum products, including aluminum casting for a wide range of industrial applications. Backed by state-of-the-art processes, our foundry ensures precision and innovation in every product we deliver – supporting the growing demand for durable aluminum in the USA.

Aluminum Cast Plate Manufacturing Applications

Aluminum cast plates are used in various industries in the end applications of everyday products, including automotive, medical, aerospace, electronics, and consumer goods.

The Aluminum Casting Process

Aluminum casting involves pouring molten aluminum into molds to create strong, durable plates. This process is vital for industries like automotive, aerospace, medical, and electronics, ensuring versatile and reliable applications.

Aluminum cast plates are used in a various industries in the end applications of everyday products, including automotive, medical, aerospace, electronics, and consumer goods. Some of the common products of aluminum plates include plastic trays, food containers, medical devices, vehicle doors and panels, refrigerator linings, machine housings, and enclosures.